Qalajiyaha crystal infrared for R-PET Pelletizing/Extrusion Line

Qalajinta Infrared Pre-engegan ee Flakes PET: Kordhinta wax soo saarka iyo horumarinta tayada PET Extruders

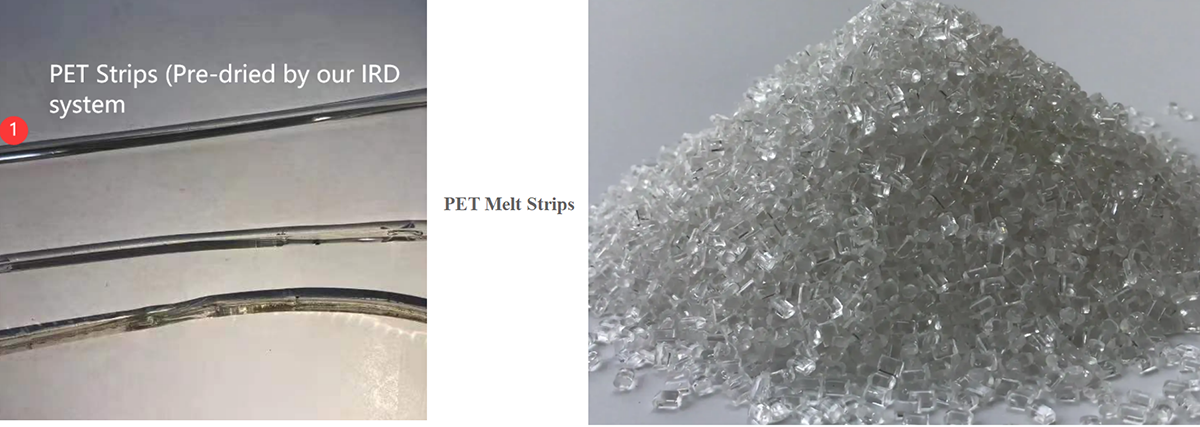

>> Dib-u-hagaajinta jajabyada ku jira qalabka wax lagu saaro waxay yareysaa IV sababtoo ah hydrolysis i joogitaanka biyaha,taasina waa sababta ka hor engejinta heer isku mid ah oo lagu qalajiyo Nidaamkayaga IRD waxay xaddidi kartaa dhimistan. Intaa waxaa dheer, resinku ma hurdi doono sababtoo ah wakhtiga qalajinta waa la dhimay (Waqtiga qalajinta kaliya wuxuu u baahan yahay 15-20mins, qoyaanka ugu dambeeya wuxuu noqon karaa≤ 50ppm, isticmaalka tamarta in ka yar 80W/KG/H), iyo xiirid ku jirta bakhtiiyaha ayaa sidaas oo kale loo dhimay sababtoo ah walxaha preheated waxay gashaa qulqulka heerkulka joogtada ah"

>>Tallaabada ugu horreysa, dib-u-kicinta PET waa la kariyey oo lagu qallajin doonaa gudaha IRD gudaha muddo ku dhow 15 daqiiqo. Hannaanka crystallization iyo engejinta waxaa lagu gaaraa habka kulaylka tooska ah iyadoo la isticmaalayo shucaaca Infrared, si loo gaaro heerkul maaddada ah 170˚C. Si ka duwan hababka hawo kulul ee qunyar socodka ah, tamarta degdega ah iyo tooska ah ee tamarta tooska ah waxay sahlaysa sinnaanta qumman ee qiimaha qoyaanka joogtada ah ee isbeddelka - nidaamka xakamaynta shucaaca IR wuxuu u oggolaanayaa ka jawaabista xaaladaha habraaca isbeddelka ee ilbiriqsiyo gudahood. Sidan, qiyamka u dhexeeya 5,000 iyo 8,000 ppm waa la dhimay si isku mid ah gudaha IRD ilaa heerka qoyaanka hadhaaga ah ee ku saabsan 30-50ppm.

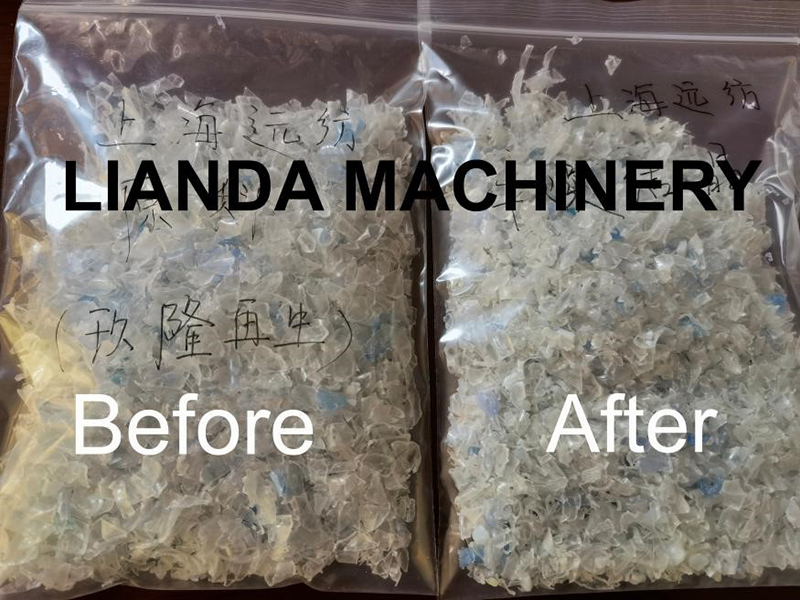

>>Sida saamaynta labaad ee habka crystallization ee IRD, cufnaanta ugu badan ee walxaha dhulka ayaa kordha,gaar ahaan qolof aad u khafiif ah. Saamayntan labaad ayaa ah mid aad u xiiso badan marka loo eego asalka in u janjeerta dhalada gidaarka dhuuban ay ka hortagto alaabta dib u warshadaynta inay gaadho cufnaanta badan ee> 0.3 kg/dm³. Korodhka cufnaanta cufnaanta 10 ilaa 20% ayaa lagu gaadhi karaa IRD, taas oo u muuqata mid aan muhiim ahayn marka la eego aragtida koowaad, laakiin waxay si weyn u wanaajisaa waxqabadka quudinta gudaha marinka extruder-ka - halka xawaaraha wax-soo-saarku aanu isbeddelin, waxaa jira horumar la taaban karo. waxqabadka buuxinta ee furka.

Waqtiga boostada: Abriil-07-2023