Xariiqda granulating-ka is haysta

Hal tillaabo tignoolajiyada PP raffia, tolmo iyo PE/PP qashinka filimka

Granulator-ka dib-u-warshadaynta filimka oo ay nashqadaysay LIANDA MACHINERY wuxuu qaataa habka wax-soo-saarka ee burburinta, kululaynta kululaynta, pelletizing iyo qalajinta, kaas oo xalliya dhibaatada:

Khatarta quudinta gacanta

■ Awoodda quudinta khasabka ah waa mid yar

■ Isticmaalka gacanta ee hawlgalka kala qaybsan ee burburinta iyo ka saarista waa weyn tahay

■ Xajmiga qayb ka mid ah xargaha ma aha mid isku mid ah, oo xargaha si fudud ayaa loo jebiyaa

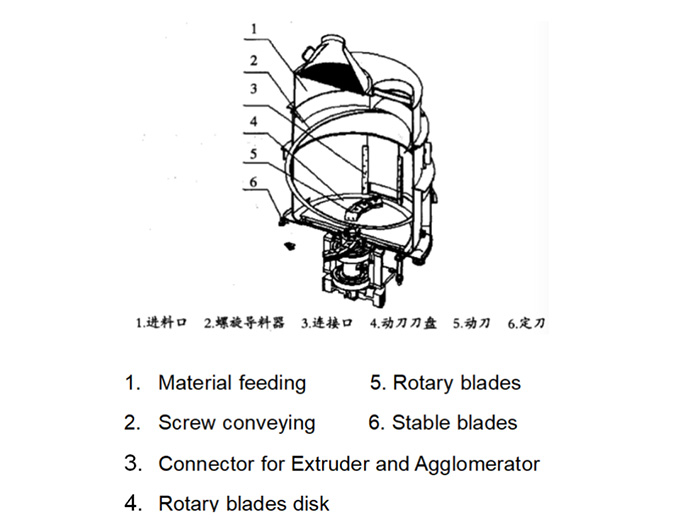

Qalabka granulation filimku wuxuu qaataa habka isku-duubnida & burburinta. Ka dib markii walxaha la quudiyo compactor-ka, waxaa lagu burburin doonaa madaxa gooyaha hoose, iyo khilaafka ka dhashay goynta xawaaraha sare ee madaxa gooyuhu waxay dhalinaysaa kulayl, si ay walaxdu u kululaato oo loo xoqdo si loo kordhiyo cufnaanta bulk maaddada oo kordhi tirada quudinta. Habkani wuxuu leeyahay caawinaad weyn si loo kordhiyo awoodda wax soo saarka

Tilmaamaha Mashiinka

| Magaca mashiinka | Xariiqda granulating-ka is haysta |

| Wax soo saarka kama dambaysta ah | Pellets/granule caag ah |

| Qaybaha wax soo saarka | Suunka wareejinta, fuustada cufka gooya, fidiyaha, unugga pelletizing, unugga qaboojinta, unugga qalajinta, haanta silo |

| Qalabka Codsiga | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Quudinta | Suunka wareejinta (Standard), quudiyaha duubka nip (Ikhtiyaar) |

| Dhexroor maroojin | 65-180mm |

| Isku dhufashada L/D | 30/1; 32/1;34/1;36/1 |

| Kala duwanaanshaha wax soo saarka | 100-1200kg/h |

| Walaxda maroojin | 38CrMoAlA |

| Degasing | Degis-fudud keli ah ama laba-laab leh, Aan loo abuurin filim aan daabacnayn (la habeeyey) Laba nooc oo marxalad ah (hooyada-ilmaha extruder) si aad u sii nadiifiso |

| Nooca goynta | Giraanta biyaha ayaa u dhinta wejiga goynta ama xadhig ayaa dhinta |

| Shaashada beddelka | Laba-meelood shaqo oo laba-jibbaaran oo shaashad beddele ah oo aan joogsi lahayn ama la habeeyey |

| Nooca qaboojinta | Biyo qaboojiye |

Faahfaahinta Mashiinka ayaa Muujiyay

>> Filimada Compactor/Agglomerator ayaa jari doona filimka oo isku duubi doona filimka iyadoo la raacayo xawaarihiisa sare

>> Aflaanta isku xidhka/ agglomerator waxaa loogu talagalay daaqad indho-indhayn si ay ugu fududayso macaamiisha inay furaan, nadiifiyaan oo beddelaan daabyada

>> Ka dib marka maaddadu gasho compactor-ka, waa la jajabiyaa oo la isku dhejiyaa, kombuyuutarka xawaaraha sare leh wuxuu ku tuurayaa walxaha hal-screw extruder ee waddada socodka. Heerkul sare ayaa lagu abuuri karaa compactor-ka, isaga oo isku dhejinaya balaastiigga pellets iyo

>> Pelletizer-biyoodka-ring, xawaaraha pelletizing waxaa gacanta ku haya inverter, oo ay ku jiraan dhimasha goynta kulul, koorta leexiyaha, daboolka biyaha-ring, haystaha mindida, disc mindida, bar mindi iwm

>> Beddelka shaashadda hayirooliga ee aan joogsiga lahayn, waxaa jira dareeme cadaadis saaran madaxa dhinta si uu u dedejiyo isbeddelka shaashadda, looma baahna in la joojiyo isbeddelka shaashadda, iyo beddelka shaashadda degdegga ah

>> pellets ayaa si toos ah loo gooyaa madaxa madaxa dhinta ee giraanta, iyo pellets waxaa lagu quudin doonaa mashiinada dewatering Vertical ka dib marka biyaha la qaboojiyo, dhibaatada xadhig jebinta ma dhici doonto;

Nidaamka Xakamaynta

■ Quudinta: qaadaha suunka ordo ama ma socdo waxay ku xiran tahay Lacagta Korontada ee Compactor/Agglomerator. Gaadhida suunka ayaa joojin doonta gudbinta iyadoo korantada filimka compactor/agglomerator uu ka sarreeyo qiimaha la dejiyay.

■ Heerkulka Filimada Compactor/Agglomerator: Heerkulka ay dhaliso is jiid jiidka walaxda waa in uu xaqiijiyaa in walaxda la kululeeyay, laalaabtay, la qantay, oo ay si habsami leh u gashay qalabka wax saaraya, oo ay saamayn gaar ah ku leedahay xawaaraha wareeg ee matoorka is haysta.

■ Xawaraha xawaaruhu wuxuu noqon karaa mid la isku hagaajin karo (Marka loo eego xigashada walxaha quudinta

■ Xawaaraha pelleting wuxuu noqon karaa mid la isku hagaajin karo (Marka loo eego wax soo saarka iyo cabbirka)