Khadka Dhalada dhalada ee PET

Tilmaamaha Farsamada

|

Magaca mashiinka |

PET Single Screw Extrusion Pelletizing Line |

|

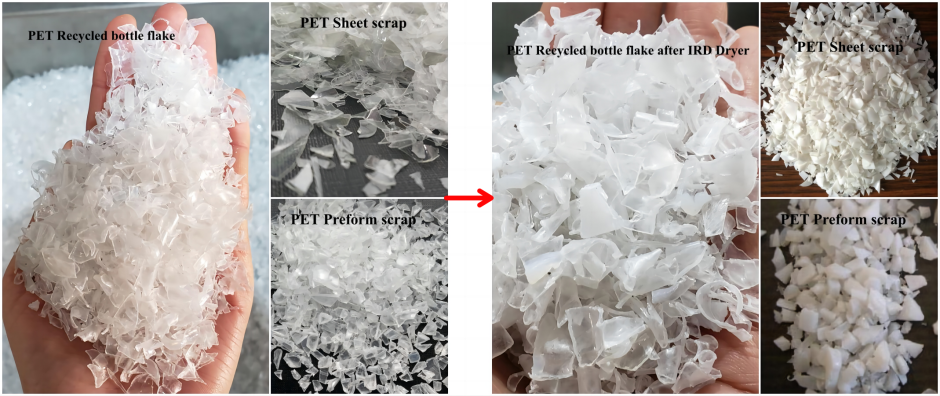

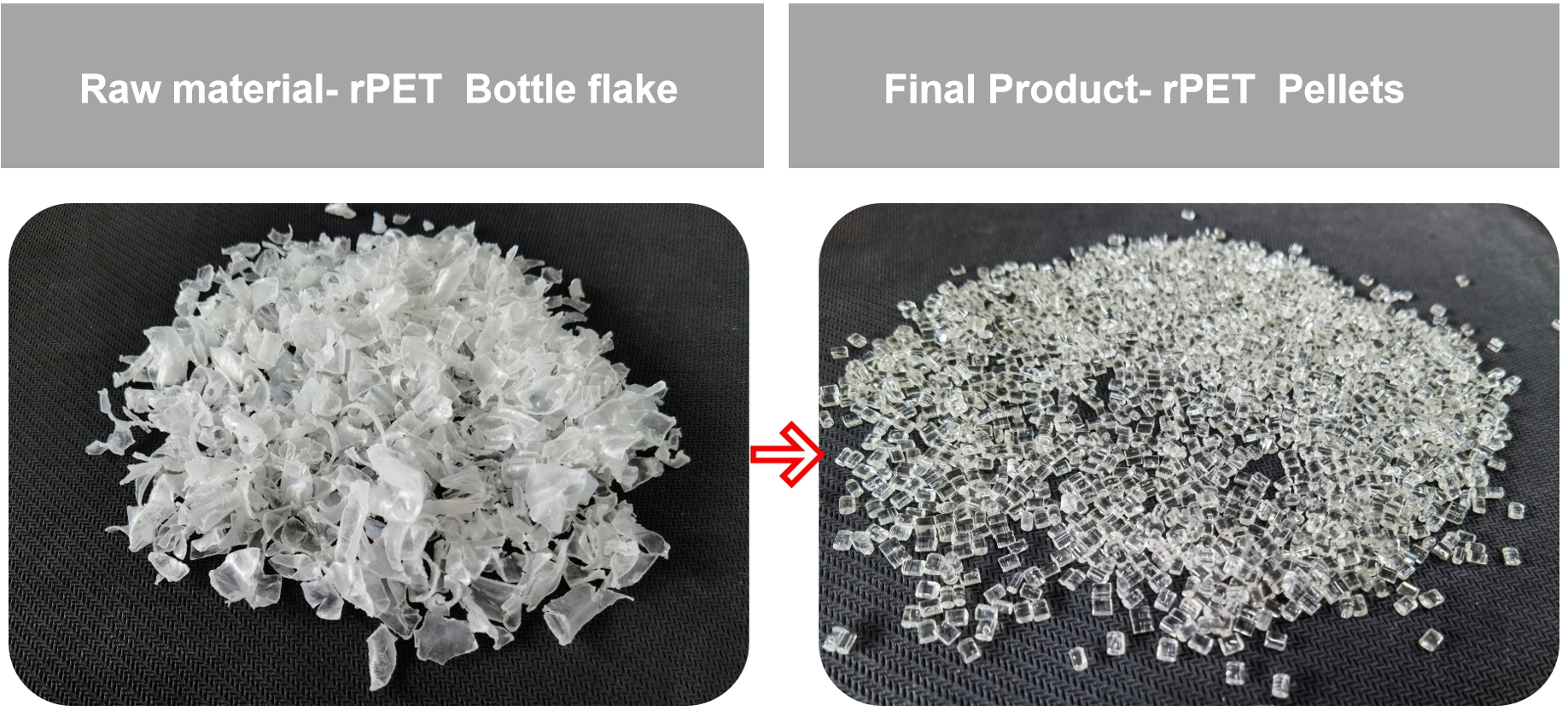

Walxaha ceeriin |

rPET Flakes |

|

Badeecada u dambaysa |

Pellets rPET |

|

Qaybaha Line Production | Habka qalajiyaha crystal infrared: Faakuum feederiyaha/ qalajiyaha crystal infrared/Fakuumka dareeraha

Hal xariiqa granulating Extrusion Screw: Iskaashatada hal baallaha ah/Beddelaha shaashada laba-laab ee Haydarooliga ah/Madaxa dhinta/ Weelka biyaha soo shubaya/Fulinaysa Pellitizer/Mashiinka dareeraha toosan/Mashiinka shaandheeyo gariiraya/ Kaydinta

|

|

Dhexroor maroojin |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Kala duwanaanshaha wax soo saarka |

150-1000KG/H |

|

Walaxda maroojin |

38CrMoAlA oo leh daawaynta Nitrding |

|

Nooca Pelletizing |

Biyo-luqidda & ka-saarista |

|

Shaashada beddelka |

Beddelaha Shaashada Haydarooliga Double Pistons |

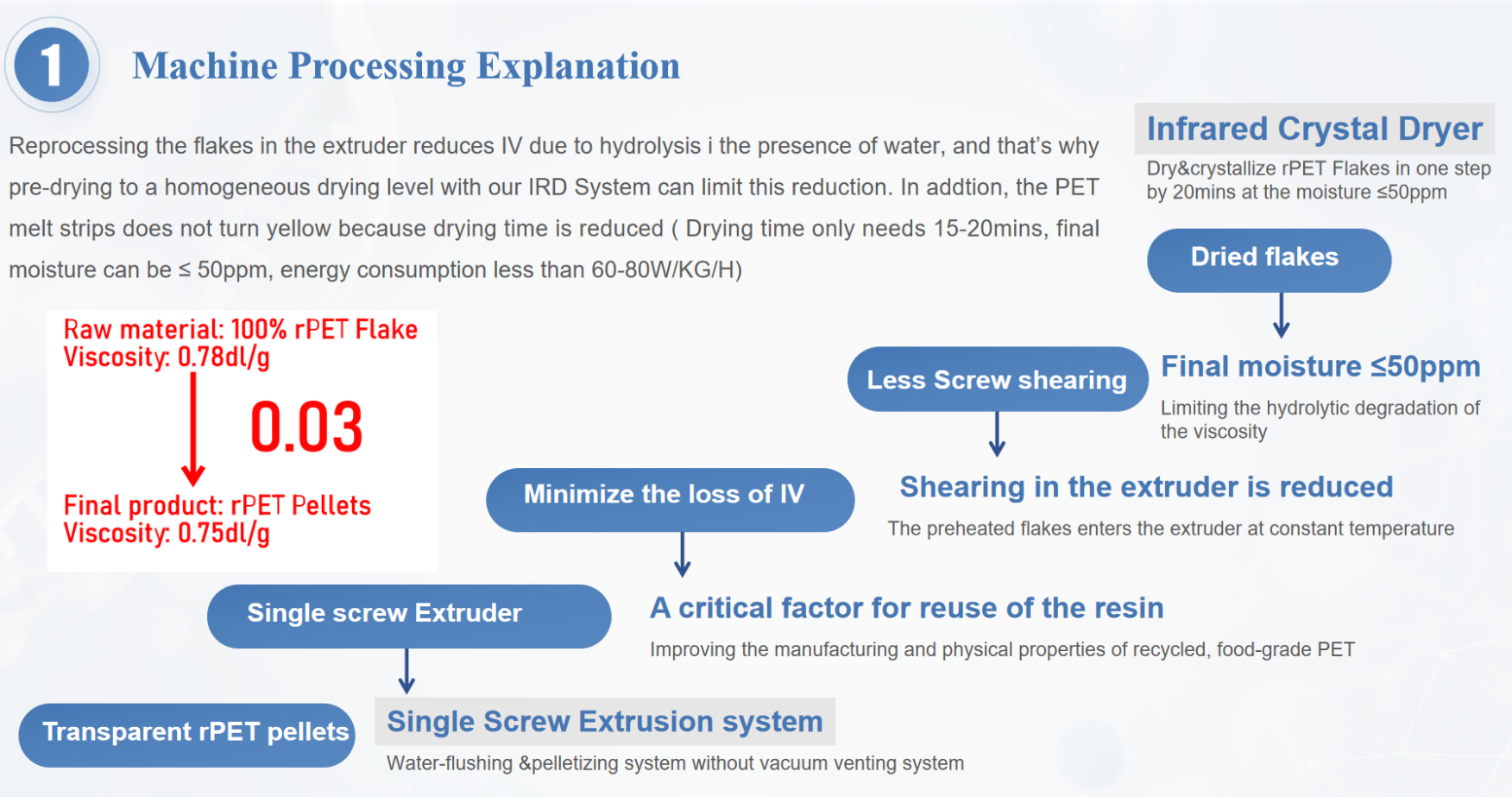

Faahfaahinta mashiinka

Qalajiyaha Infrared Crystal (LIANDA PATENT DESIGN)

① Hagaajinta wax soo saarka iyo sifooyinka jireed ee dib loo warshadeeyay, heerka cuntada PET iyada oo loo marayo tignoolajiyada ku shaqeeya mowjadda infrared ayaa qayb muhiim ah ka ah in laga ciyaaro maalka gudaha (IV)

②Cristallization ka hor & qallajinta jajabyada ka hor inta aan dibadda loo saarin waxay gacan ka geysataa dhimista luminta IV ee PET, oo ah arrin muhiim u ah dib u isticmaalida xabagta

③ Dib-u-habaynta jajabyada ku jira qalabka wax-soo-saarku waxay yaraynaysaa IV sababtoo ah hydrolysis ee joogitaanka biyaha, taasina waa sababta ka-hor-u-qallajinta heerka qalajinta isku mid ah ee Nidaamkayaga IRD wuxuu xaddidi karaa dhimistan.

Intaa waxaa dheer, xariijimaha dhalaalista ee PET uma rogaan huruud sababtoo ah wakhtiga qalajinta waa la dhimay (Waqtiga qalajinta kaliya wuxuu u baahan yahay 15-20mins, qoyaanka ugu dambeeya wuxuu noqon karaa ≤ 30ppm, isticmaalka tamarta wax ka yar 60-80W/KG/H)

④ Shearing in extruder-ka ayaa sidoo kale la dhimay sababtoo ah walxaha preheated waxay gashaa qulqulka heerkulka joogtada ah"

⑤Hagaajinta wax soo saarka PET Extruder

Kordhinta cufnaanta guud ee 10 ilaa 20% ayaa lagu gaadhi karaa IRD, waxay si weyn u wanaajisaa waxqabadka quudinta marinka extruder-ka - halka xawaaraha wax-saarku uu yahay mid aan isbeddelin, waxaa si weyn loo hagaajiyay waxqabadka buuxinta daboolka.

Khadka Pelletizing Extrusion Screw Single (La'aanteed Vacuum Venting)

Anaga oo adeegsanayna awoodaha kaashashka Keliga ah oo aan ku barbar dhignay LIANDA si gaar ah loogu nashqadeeyay sharoobada dhalada rPET, waxa aanu awoodnay in aanu kordhino awoodda 20% iyada oo aan isticmaalnay awood yar marka la barbar dhigo barbar-baxa labajibbaaran ee kaashashka.

Viscosity ee pellets rPET ee uu soo saaray nidaamkeenu: waxaa jira kaliya ≤0.02-0.03dl/g hoos udhaca viscosity ---iyada oo aan lagu darin wax kor u qaadaya viscosity. (Marka loo eego baaritaanka guriga dhexdiisa)

pellets rPET Midabka: hufan --- adigoon ku darin wax kor u qaadaya hufnaanta

Nidaamka hawo-mareenka Vacuum la'aanteed --- Badbaadinta qiimaha tamarta, dhib la'aan iyo shaqeyn xasilloon

Sawirada Mashiinka