PET Granulating line

Qalajiyaha Infrared Crystallization ee khadka granulating ee rPET Extrusion

Qalajinta Infrared Pre-engegan ee Dhalooyinka rPET: Kordhinta wax soo saarka iyo horumarinta tayada PET Extruders

Qallajintu waa doorsoomaha keliya ee ugu muhiimsan hab-socodka.

>> Hagaajinta wax soo saarka iyo sifooyinka jireed ee dib loo warshadeeyay, heerka cuntada PET iyada oo loo marayo tignoolajiyada ku shaqeeya iftiinka infrared ayaa qayb muhiim ah ka ciyaaraya maaddada gudaha (IV)

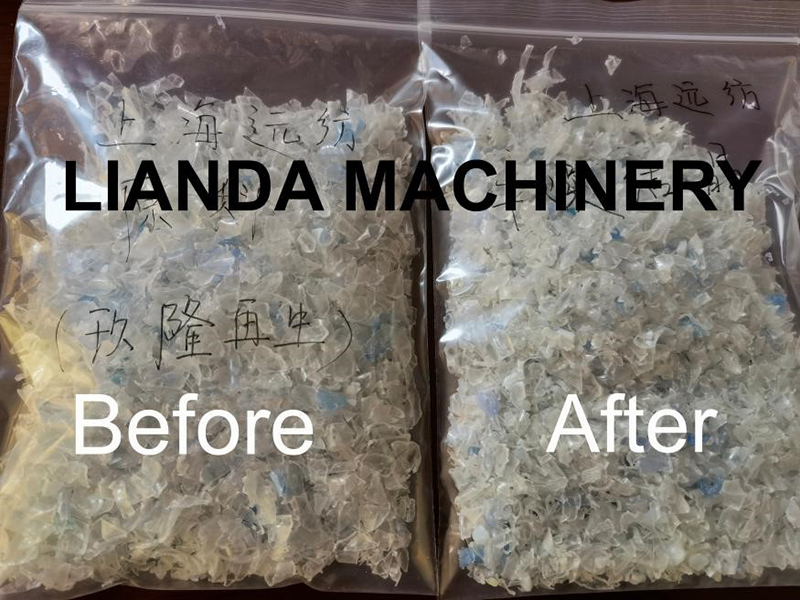

>> Pre-crystalization & qallajinta jajabyada ka hor inta aan la saarin waxay yaraynaysaa lumitaanka IV ee PET, oo ah arrin muhiim u ah dib-u-isticmaalka xabagta

>> Dib-u-hagaajinta jajabyada ku jira bakhtiiyaha waxay yaraynaysaa IV sababtoo ah hydrolysis i joogitaanka biyaha, taasina waa sababta ka hor-engejinta heerka qalajinta siman ee Nidaamkayaga IRD wuxuu xaddidi karaa dhimistan. Intaa waxaa dheer.Xariijimaha dhalaalista ee PET ma isu beddelaan jaalle sababtoo ah wakhtiga qallajinta waa la dhimay(Waqtiga qalajinta kaliya wuxuu u baahan yahay 15-20mins, qoyaanka ugu dambeeya wuxuu noqon karaa ≤ 30ppm, isticmaalka tamarta wax ka yar 80W/KG/H)

>> Xiritaanka qalabka wax-soo-saarka ayaa sidoo kale la dhimay sababtoo ah walxaha horay loo sii kululeeyay waxay galaa qulqulka heerkulka joogtada ah

>>Hagaajinta wax soo saarka PET Extruder

Kordhinta cufnaanta guud ee 10 ilaa 20% ayaa lagu gaadhi karaa IRD, waxay si weyn u wanaajisaa waxqabadka quudinta marinka extruder-ka - halka xawaaraha wax-saarku uu yahay mid aan isbeddelin, waxaa si weyn loo hagaajiyay waxqabadka buuxinta daboolka.

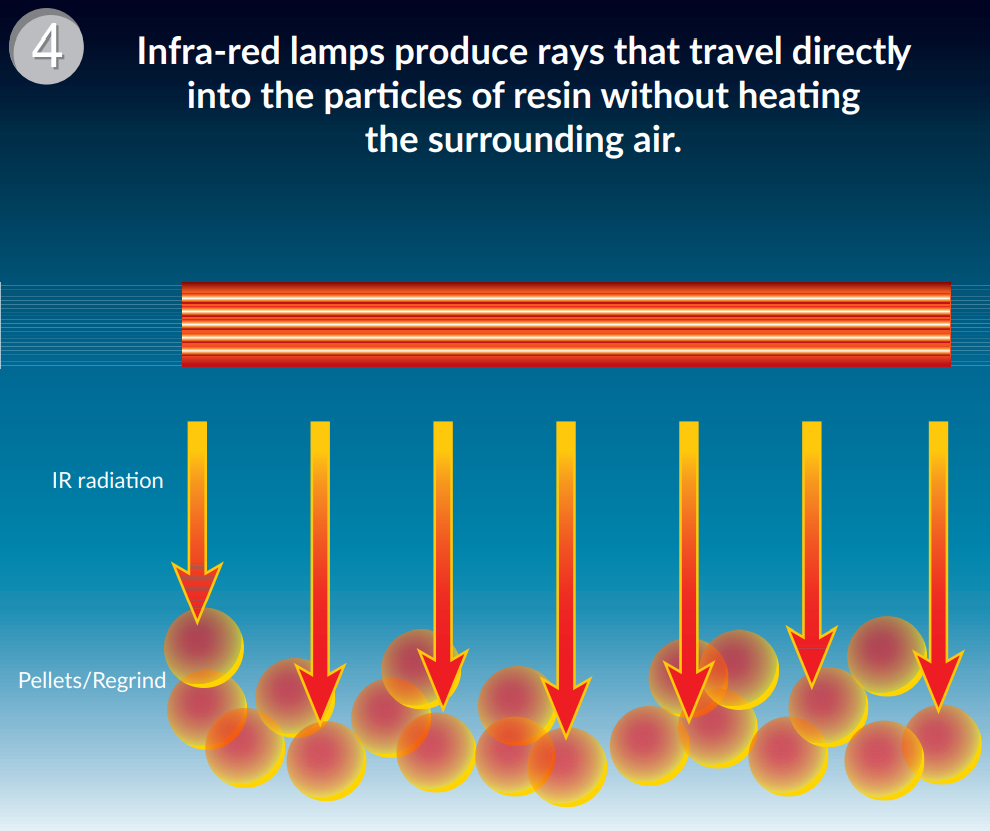

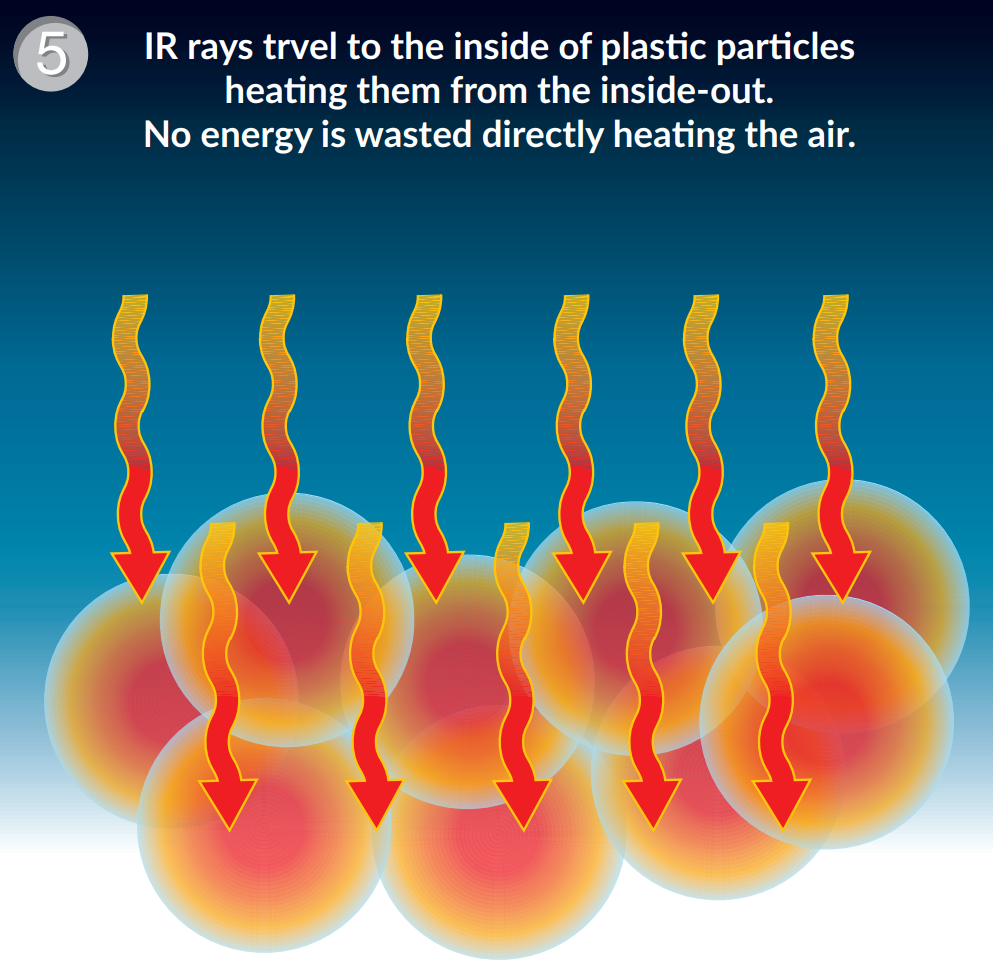

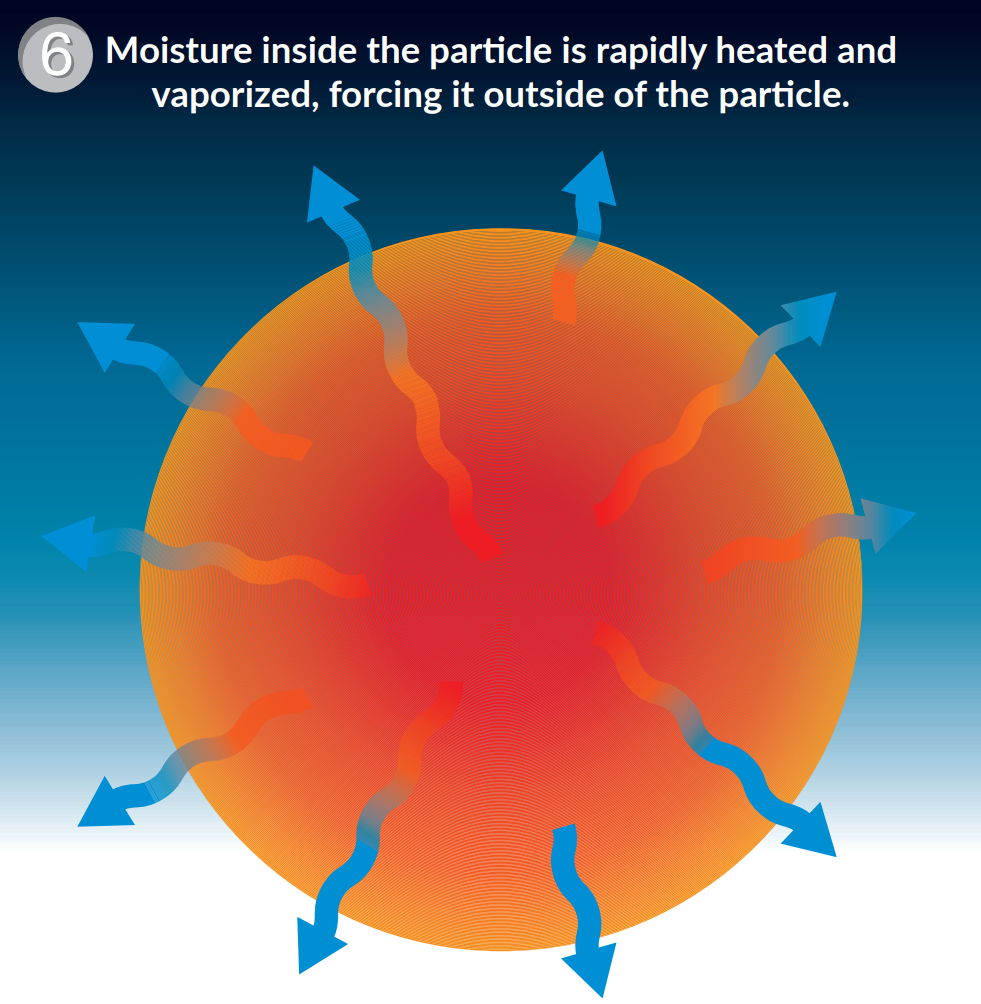

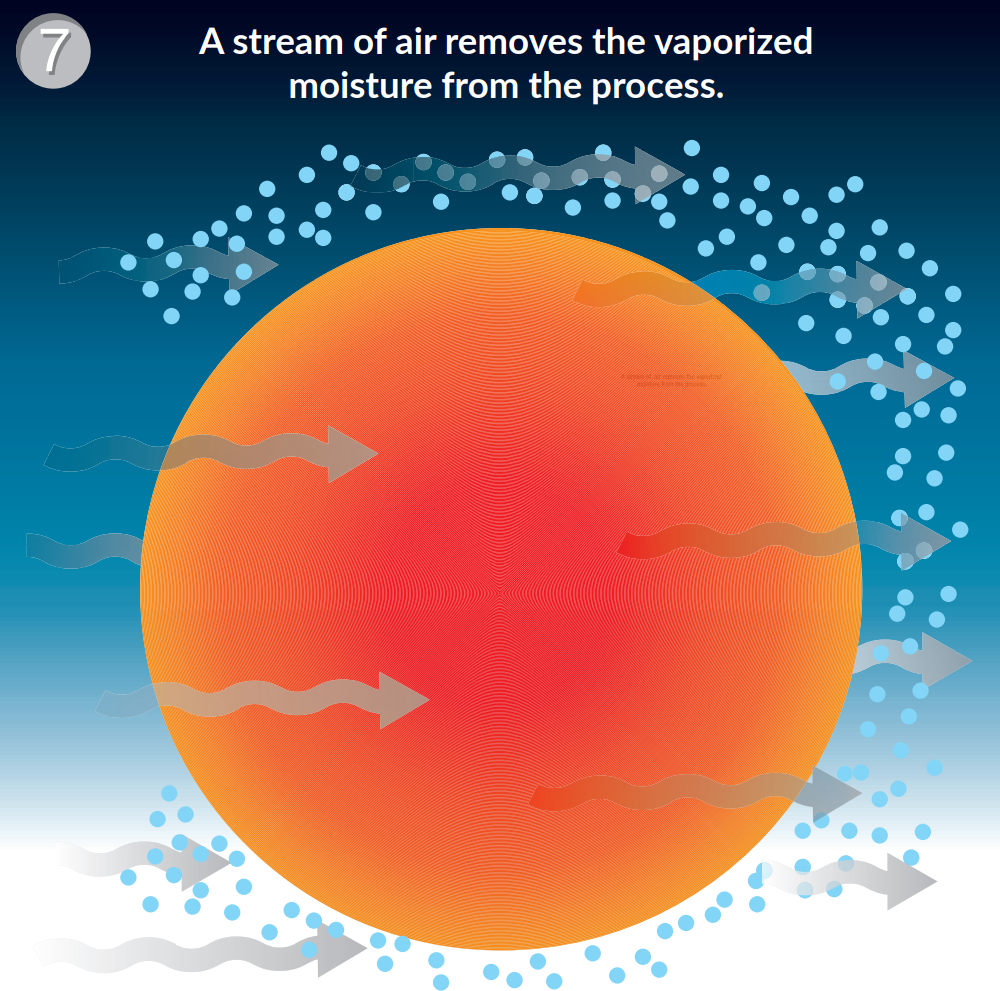

Mabda'a Shaqada

Faa'iidada aan Sameyno

※Xaddidaadda hoos u dhaca hydrolytic ee viscosity.

※ Kahortagga kordhinta heerarka AA ee agabka cuntada leh

※ Kordhinta awoodda khadka wax soo saarka ilaa 50%

※ Hagaajinta oo ka dhig tayada badeecada mid xasiloon -- Isku mid ah oo lagu celin karo nuxurka qoyaanka agabka

→ Yaree kharashka wax soo saarka ee pellets PET: Ilaa 60% isticmaalka tamarta ka yar habka qalajinta caadiga ah

→ Bilawga degdega ah oo dhaqso u xidh --- Looma baahna kulayl ka hor

→ Qallajinta& kristaliynta waxa lagu farsamayn doonaa hal tallaabo

→ Khadka mishiinku wuxuu ku qalabaysan yahay nidaamka Siemens PLC oo leh hal shaqo oo xusuusta muhiimka ah

→ Waxay dabooshaa aag yar, qaab dhismeed fudud oo sahlan in lagu shaqeeyo laguna dayactiro

→ Heerkulka madax-bannaan iyo wakhtiga qallajinta oo go'an

→ Ma kala soocna alaabooyinka leh cufnaanta cufnaanta kala duwan

→ Si fudud oo nadiif ah oo beddel walxaha

Mashiinka Ku shaqeeya warshadda Macmiilka

FAQ

S: Waa maxay qoyaanka ugu dambeeya ee aad heli karto? Ma leedahay wax xaddidaad ah qoyaanka bilowga ah ee alaabta ceeriin?

J: Qoyaanka ugu dambeeya waxaan heli karnaa ≤30ppm (Tusaale u qaado PET). Qoyaanka hore wuxuu noqon karaa 6000-15000ppm.

S: Waxaan u isticmaalnaa laba-geesood isbarbar socda oo leh nidaamka degeyska faakuumka ee khadka granulating PET Extrusion, weli miyaynu u baahanahay inaan isticmaalno qalajiyaha hore?

J: Waxaan soo jeedinaynaa in la isticmaalo Pre-qalajiyaha ka hor inta aan la saarin. Sida caadiga ah nidaamka noocan oo kale ah wuxuu leeyahay shuruud adag oo ku saabsan qoyaanka bilowga ah ee alaabta PET. Sida aan ognahay PET waa nooc ka mid ah maaddooyinka nuugi kara qoyaanka jawiga taas oo keeni doonta in xariiqda extrusion si xun u shaqeyso. Markaa waxaan kugula talineynaa inaad isticmaasho qalajiyaha ka hor nidaamkaaga extrusion:

>> Xakamaynta nabaad-guurka (hydrolytic deradation) ee viscosity

>>Kahortagga kordhinta heerarka AA ee agabka cuntada leh

>> Kordhinta awoodda khadka wax soo saarka ilaa 50%

>> Hagaajinta oo ka dhig tayada badeecada mid xasiloon -- Isku mid ah oo lagu celin karo nuxurka qoyaanka agabka

S: Waa maxay wakhtiga keenista IRD kaaga?

A: 40 maalmood oo shaqo tan iyo markii aan ka helno deebaajigaaga akoonnada shirkadda.

S: Sidee ku saabsan rakibidda IRD kaaga?

Injineer khibrad leh ayaa kaa caawin kara rakibidda nidaamka IRD ee warshadaada. Ama waxaan ku bixin karnaa adeegga hagaha khadka. Mashiinka oo dhan wuxuu qaataa fiilada duulista, oo u fududahay isku xirka.

S: Waa maxay IRD lagu codsan karaa?

J: Waxay hore u qallajin kartaa

- PET/PLA/TPE Sheet khadka mashiinka extrusion

- PET Bale suunka samaynta khadka mashiinka

- PET masterbatch crystallization iyo qalajinta

- PETG Sheet line extrusion

- Mashiinka monofilament PET, PET monofilament line extrusion, monofilament PET ee xaaqinka

- Mashiinka samaynta filimka PLA /PET

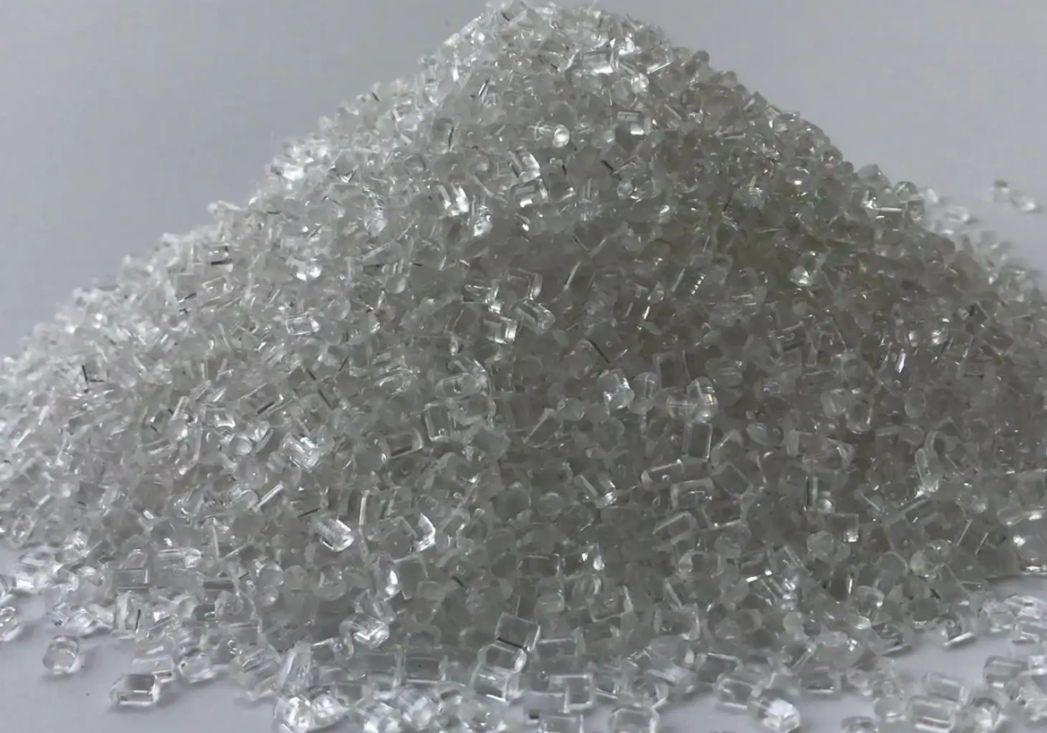

- PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET ( Dhalooyinka, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS iwm.

- Hababka kulaylka eeka saarista nasashada oligomeren iyo qaybaha kacsan.