Qalajiyaha caaga ah

Tusaalaha Codsiga

| Walxaha ceeriin | Pellets PET (waxaa sameeyay flake dib loo warshadeeyay) |  |

| Isticmaalka Mashiinka | LDHW-600*1000 |  |

| Dejinta heerkulka crystallized | 200℃ | |

| waqti go'an crystallized | 20 daqiiqo | |

| Waxyaabaha ugu dambeeya | Pellets PET crystallized |  |

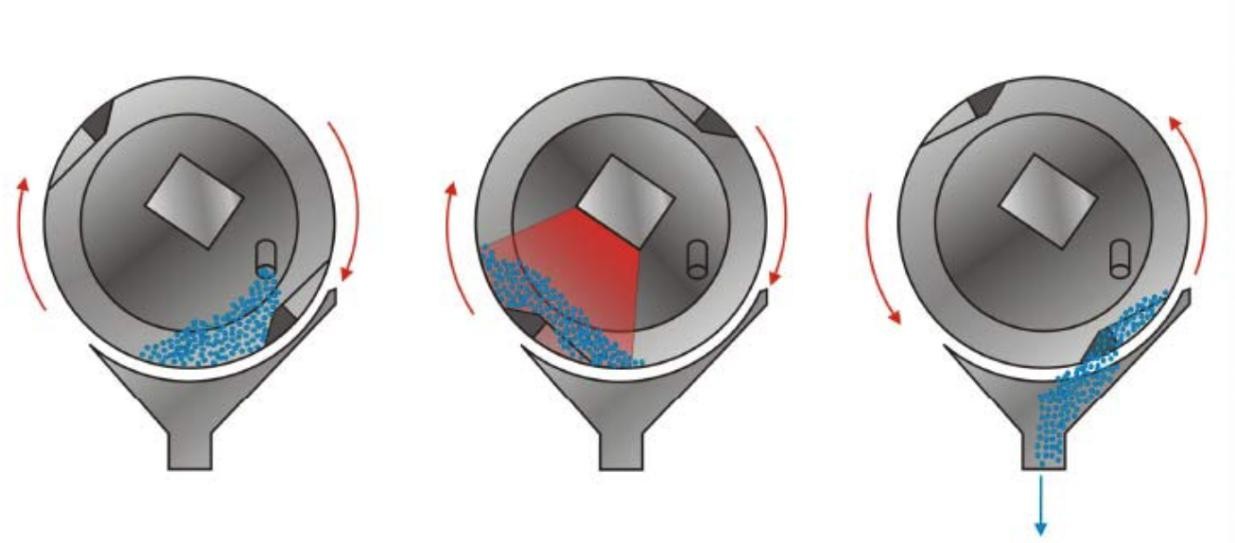

Sida Loo Shaqeeyo

>>Talaabada ugu horeysa, bartilmaameedka kaliya ayaa ah in la kululeeyo walxaha ilaa heerkul hore loo dejiyay.

Qabo xawli gaabis ah ee durbaanka wareega, awooda nalalka Infrared ee qalajiyaha waxay ahaan doontaa heer sare, ka dib pellets-yada PET waxay yeelan doonaan kuleyl degdeg ah ilaa heerkulku kor ugu kaco heer kulka hore.

>> Qalajinta & Tallaabada kristalling

Marka maaddadu ay gaarto heerkulka, xawaaraha durbaanka ayaa lagu kordhin doonaa xawaare wareeg ah oo aad u sarreeya si looga fogaado isku-duubnaanta walxaha. Isla mar ahaantaana, awoodda nalalka infrared ayaa mar kale kordhin doona si loo dhammeeyo qalajinta. Kadibna xawaaraha wareega durbaanka ayaa mar kale hoos loo dhigi doonaa. Sida caadiga ah habka qalajinta ayaa la dhammeeyaa 15-20mins ka dib. (Waqtiga saxda ah wuxuu ku xiran yahay hantida maaddada)

>>Ka dib marka la dhammeeyo habka qalajinta, IR Drum si toos ah ayuu u soo daayaa alaabta oo dib u buuxin doonaa durbaanka wareegga xiga.

Dib-u-buuxinta tooska ah iyo sidoo kale dhammaan cabbirrada laxiriirta ee heerkulbeegyada kala duwan waxay si buuxda u dhexgalaan kontoroolka shaashadda taabashada ee casriga ah. Marka cabbiraadaha iyo astaamaha heerkulka la helo shay gaar ah, goobaha teess-ka waxaa loo keydin karaa sida cuntada ee nidaamka xakamaynta.

Faa'iidadayada

Ilaa 60% isticmaalka tamarta ka yar habka qalajinta caadiga ah

Ma jiro kala soocid alaabooyinka leh cufnaanta cufnaanta kala duwan

Heerkulka madax banaan iyo wakhtiga qalajinta

Nadiifin fudud oo beddel walxaha

Bilawga degdega ah oo dhaqso u xidh

crystallization lebbiska

Ma jiraan pellets ku boodboodaya & dheg

Daawaynta alaabta si taxadar leh

Sawirada Mashiinka

Codsiga Mashiinka

| Kululaynta | Kuleyliyaha kuleyliyaha iyo walxaha dib-u-kicin ka hor farsamaynta dheeraadka ah (tusaale PVC, PE, PP,…) si loo hagaajiyo wax soo saarka habka extrusion. |

| Crystallization | Karistalaynta PET (dhalada dhalada, granules, flakes), PET masterbatch, co-PET, PBT, PEEK, PLA, PPS, iwm. |

| Qalajinta | Qallajinta bacaha, iyo walxaha dhulka (tusaale, PET, PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU) iyo sidoo kale qalabyo kale oo bilaash ah. |

| Qoyaanka soo galitaanka sare leh | Habka qalajinta ee leh qoyaan badan> 1% |

| Kala duwan | Nidaamyada kuleylka ee ka saarista oligomers nasashada iyo qaybaha kacsan. |

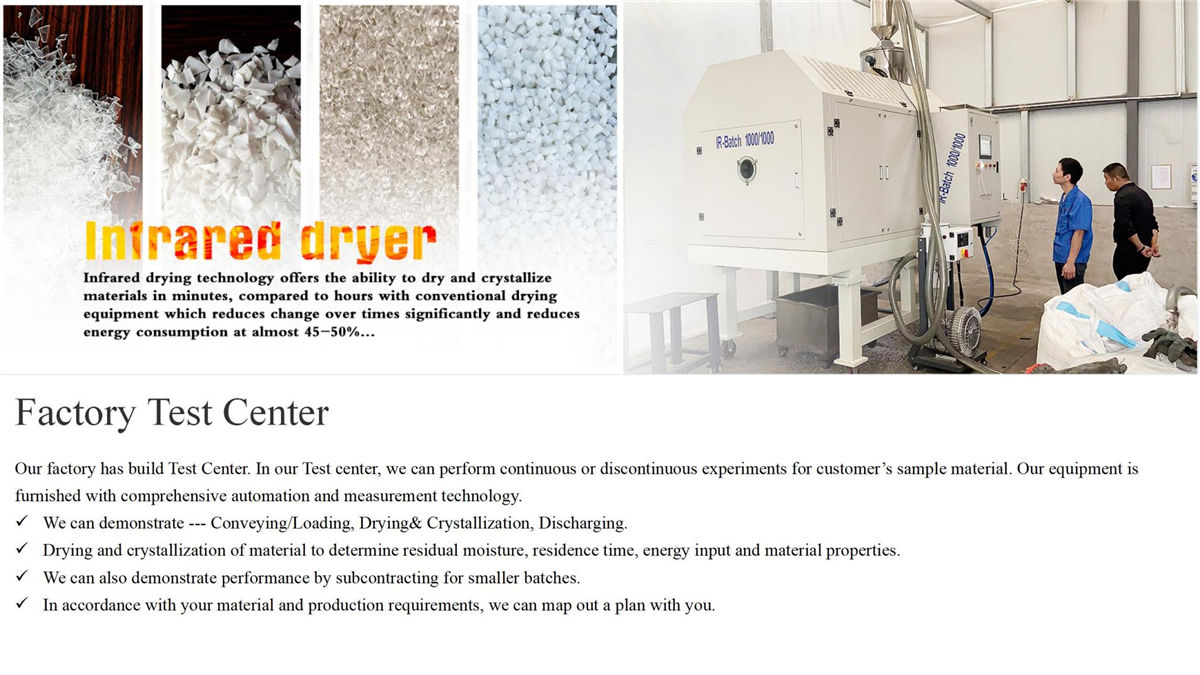

Tijaabinta Walxaha Xorta ah

Injineer khibrad leh ayaa samayn doona imtixaanka. Shaqaalahaaga si xushmad leh ayaa loogu martiqaaday inay ka qaybqaataan waddooyinka wadajirka ah. Markaa waxaad haysataa labadaba suurtogalnimada inaad si firfircoon uga qayb qaadato iyo fursadda aad si dhab ah u aragto alaabadayada oo shaqaynaya.

Rakibaadda mashiinka

>> U keen injineer khibrad leh warshadaada si uu kaaga caawiyo rakibaadda iyo tijaabinta agabka

>> Qabo fur aviation-ka, looma baahna in lagu xidho fiilada korantada inta uu macmiilku ka helayo mishiinka warshadiisa. Si loo fududeeyo tallaabada rakibidda

>> Keen fiidiyoowga hawlgalka si loogu rakibo iyo hagaha socodsiinta

>> Taageerada adeegga khadka