PLA PET heerkul-samaynta khadka xaashida extrusion

Qalajiyaha crystal infrared+ PET Sheet line Extrusion

Faa'iidada aan samayno

>>LIANDA ayaa horumarisaXariiqa fur-fure ee kali ah oo leh qalajiyaha crystal infraredloogu talagalay xaashida PET, 20mins ka hor qalajinta iyo crystallization, qoyaanka ugu dambeeya wuxuu noqon karaa ≤50ppm

Khadka extrusion wuxuu leeyahay sifooyinka isticmaalka tamarta hooseeya, habka wax soo saarka fudud iyo dayactirka sahlan.

Qaab dhismeedka furaha ee kala qaybsan wuxuu yarayn karaa luminta viscosity ee xuubka PET, duubka calender-ka simmetrical iyo dhuuban wuxuu hagaajiyaa saamaynta qaboojinta, awoodda iyo tayada xaashida.

Qaybaha badan ee qiyaasta quudiyaha ayaa koontaroolaya boqolkiiba walxaha cusub, alaabta dib-u-warshadaynta iyo dufcada ugu fiican,.

Xaashida ayaa si weyn loogu isticmaalay warshadaha baakadaha heerkulbeegga.

>>Qalajiyaha crystal infrared ---qallaji & crystallize R-PET flakes/chips gudaha 20mins at 30ppm adoo badbaadinaya 45-50% kharashka tamarta.

※Xaddidaadda hoos u dhaca hydrolytic ee viscosity.

※ Kahortagga kordhinta heerarka AA ee agabka cuntada leh

※ Kordhinta awoodda khadka wax soo saarka ilaa 50%

※ Hagaajinta oo ka dhig tayada badeecada mid xasiloon -- Isku mid ah oo lagu celin karo nuxurka qoyaanka agabka

Yaree kharashka wax soo saarka ee xaashida PET: Ilaa 60% isticmaalka tamarta ka yar habka qalajinta caadiga ah

Bilawga degdega ah oo dhaqso u xidh --- Looma baahna kulayl ka hor

Qalajinta & kiriimaynta waxa lagu farsamayn doonaa hal tallaabo

Si loo hagaajiyo xoogga xajinta xaashida PET, Kordhi qiimaha lagu daray--- Qoyaanka ugu dambeeya wuxuu noqon karaa ≤30ppm 20minsQalalan & crystallization

- Khadka mashiinku wuxuu ku qalabaysan yahay nidaamka Siemens PLC oo leh hal shaqo oo xusuusta muhiimka ah

- Waxay dabooshaa aag yar, qaab dhismeed fudud oo sahlan in lagu shaqeeyo laguna dayactiro

- Heerkulka madax banaan iyo wakhtiga qalajinta

- Ma jiro kala soocid alaabooyinka leh cufnaanta cufnaanta kala duwan

- Nadiifin fudud oo beddel walxaha

>> PET Khadka mashiinka Extrusion

| Qaabka | Lakab badan | Lakab keli ah | Aad u hufan |

| Faahfaahinta Extruder | LD75 & 36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Dhumucda alaabta | 0.15-1.5mm | 0.15-1.5mm | 0.15-1.5mm |

| Awoodda dhaqdhaqaaqa ugu weyn | 110kw/45kw | 110kw | 250kw/55kw |

| Awoodda ugu badan ee extrusion | 500kg/h | 450kg/h | 800-1000kg/h |

Liiska mashiinka

| Halabuurka Mashiinka | ||

| NO | Mashiinka | Tirada |

| 1 | PET Infrared crystal qalajiyaha | 1 set |

| 2 | Faakiyum furka feedhaha | 1 set |

| 3 | Kaashashka laba jibbaaran | 1 set |

| 4 | Vacuum nidaamka cadaadiska xun | 1 set |

| 5 | Shaandhaynta kanaalka labanlaab ah | 1 set |

| 6 | Bamka cabbiraadda dhalaalay | 1 set |

| 7 | PET caaryada gaarka ah ayaa dhinta | 1 set |

| 8 | Qayb samaynta calending saddex-duuban | 1 set |

| 9 | Dahaarka saliidda silikoon iyo aaladda foornada | 1 set |

| 10 | Qalabka goynta walxaha Edge | 1 set |

| 11 | Qalabka soo kabashada alaabta gees | 1 set |

| 12 | Nidaamka dabaysha ee labajibbaaran | 1 set |

| 13 | SIEMENS nidaamka xakamaynta isdhexgalka mashiinka-mashiinka | 1 set |

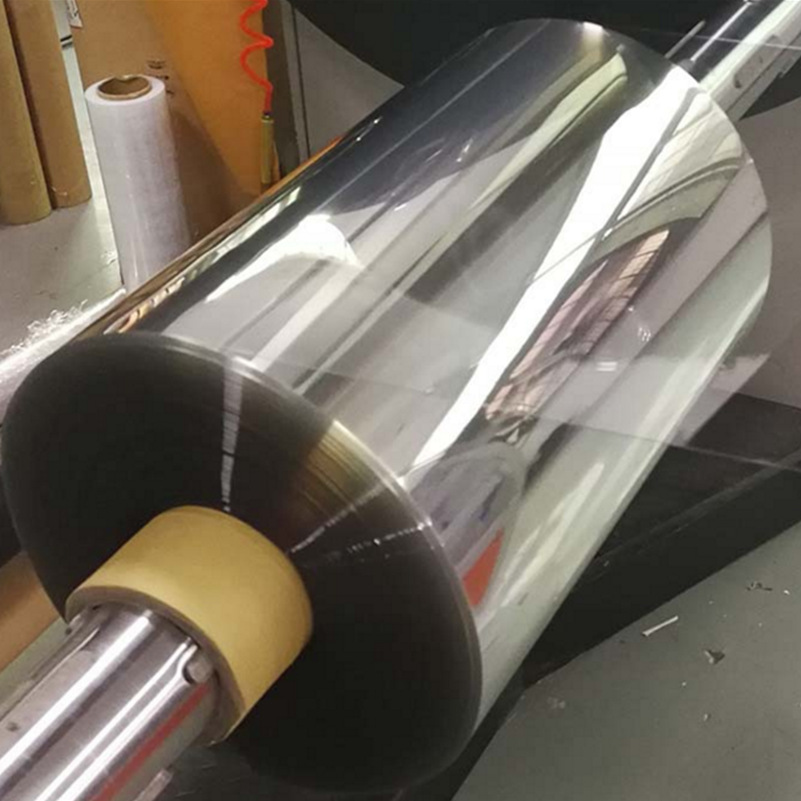

Sawirada Mashiinka

FAQ

S: Waa maxay qoyaanka ugu dambeeya ee aad heli karto? Ma leedahay wax xaddidaad ah qoyaanka bilowga ah ee alaabta ceeriin?

J: Qoyaanka ugu dambeeya waxaan heli karnaa ≤30ppm (Tusaale u qaado PET). Qoyaanka hore wuxuu noqon karaa 6000-15000ppm.

S: Waxaan isticmaalnaa laba-geesood oo isbar-bar socda oo leh nidaamka degeyska faakuumka ee daminta xaashida PET, miyaynu weli u baahanahay inaan isticmaalno qalajiyaha?

J: Waxaan soo jeedinaynaa in la isticmaalo Pre-qalajiyaha ka hor inta aan la saarin. Sida caadiga ah nidaamka noocan oo kale ah wuxuu leeyahay shuruud adag oo ku saabsan qoyaanka bilowga ah ee alaabta PET. Sida aan ognahay PET waa nooc ka mid ah maaddooyinka nuugi kara qoyaanka jawiga taas oo keeni doonta in xariiqda extrusion si xun u shaqeyso. Markaa waxaan kugula talineynaa inaad isticmaasho qalajiyaha ka hor nidaamkaaga extrusion:

>> Xakamaynta nabaad-guurka (hydrolytic deradation) ee viscosity

>>Kahortagga kordhinta heerarka AA ee agabka cuntada leh

>> Kordhinta awoodda khadka wax soo saarka ilaa 50%

>> Hagaajinta oo ka dhig tayada badeecada mid xasiloon -- Isku mid ah oo lagu celin karo nuxurka qoyaanka agabka

S: Waxaan isticmaaleynaa walxo cusub, laakiin wax khibrad ah uma lihin qalajinta alaabtaas. Ma naga caawin kartaa?

J: Warshadayadu waxay leedahay Xarunta Imtixaanka. Xaruntayada Imtixaanka, waxaan ku samayn karnaa tijaabooyin joogto ah ama joogsi ah oo loogu talagalay alaabta muunada macaamiisha. Qalabkeenu waxa lagu diyaariyey farsamaynta iyo tignoolajiyada cabbiraadda oo dhamaystiran.

Waxaan muujin karnaa --- Qaadista/Rarista, Qalajinta & Karti-saarista, Bixinta.

Qalajinta iyo crystallization ee walxaha si loo go'aamiyo qoyaan hadhaaga ah, wakhtiga joogitaanka, tamar gelin iyo sifooyinka alaabta.

Waxaan sidoo kale muujin karnaa wax qabad annagoo qandaraas-hoosaad kula galnay kooxo yaryar.

Iyadoo la raacayo shuruudahaaga alaabta iyo wax soo saarka, waxaanu kula samayn karnaa qorshe.

Injineer khibrad leh ayaa samayn doona imtixaanka. Shaqaalahaaga si xushmad leh ayaa loogu martiqaaday inay ka qaybqaataan waddooyinka wadajirka ah. Markaa waxaad haysataa labadaba suurtogalnimada inaad si firfircoon uga qayb qaadato iyo fursadda aad si dhab ah u aragto alaabadayada oo shaqaynaya.

S: Waa maxay wakhtiga keenista IRD kaaga?

A: 40 maalmood oo shaqo tan iyo markii aan ka helno deebaajigaaga akoonnada shirkadda.

S: Sidee ku saabsan rakibidda IRD kaaga?

Injineer khibrad leh ayaa kaa caawin kara rakibidda nidaamka IRD ee warshadaada. Ama waxaan ku bixin karnaa adeegga hagaha khadka. Mashiinka oo dhan wuxuu qaataa fiilada duulista, oo u fududahay isku xirka.

S: Waa maxay IRD lagu codsan karaa?

J: Waxay hore u qallajin kartaa

PET/PLA/TPE Sheet khadka mashiinka extrusion

PET Bale suunka samaynta khadka mashiinka

PET masterbatch crystallization iyo qalajinta

PETG Sheet line extrusion

Mashiinka monofilament PET, PET monofilament line extrusion, monofilament PET ee xaaqinka

Mashiinka samaynta filimka PLA /PET

PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET ( Dhalooyinka, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS iwm.

Hababka kulaylka eeka saarista nasashada oligomeren iyo qaybaha kacsan.